On Farm Scanning: Emsland Brüterei

Real time stock control of hatching eggs at all farms and trucks

On Farm Scanning in practice

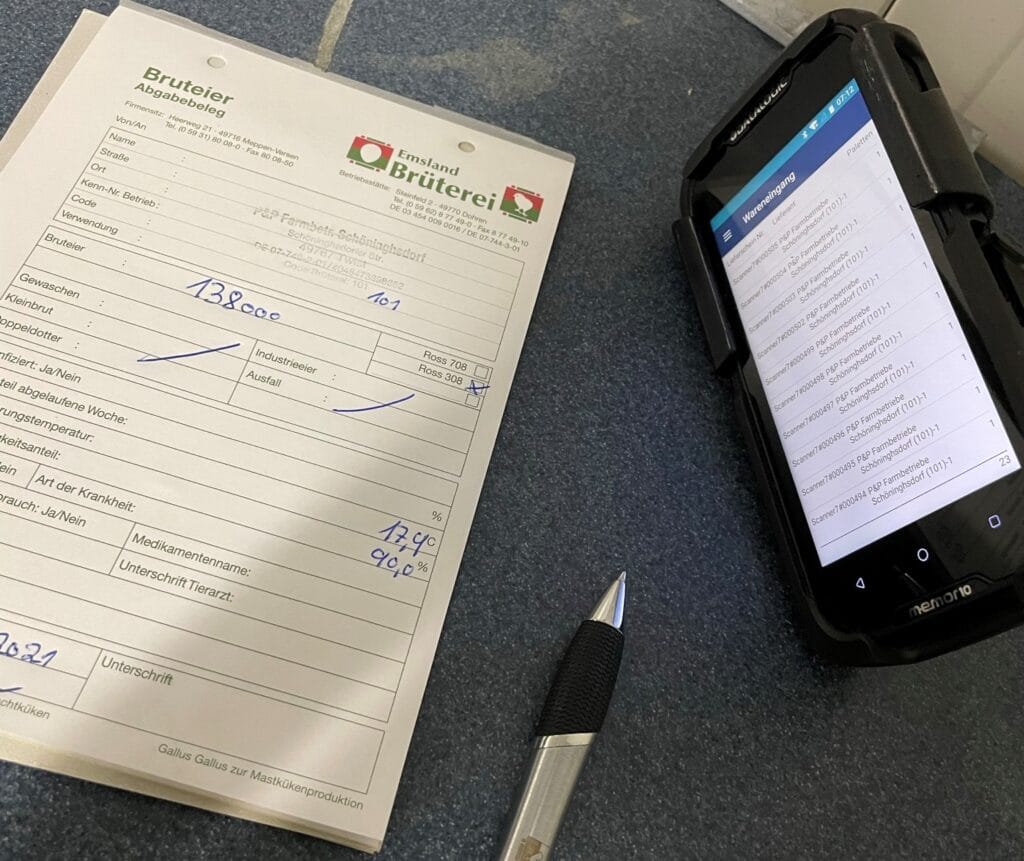

With different software modules, Hatchtrack is covering all production steps in the hatchery process. To get more insight in the production, there are also options to use Hatchtrack outside your facility. One example is hatchtrack On Farm Scanning, which is used to receive eggs remotely from farms.

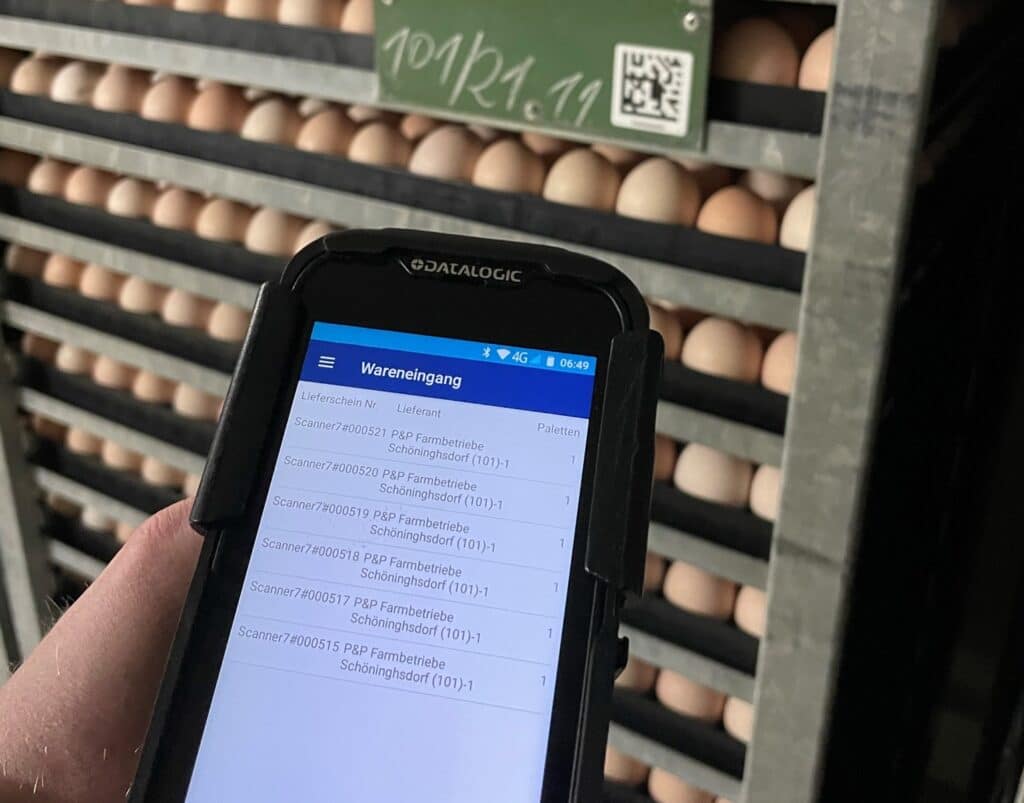

This module uses Android mobile pocket PC’s and can be used by your truck drivers or even by your farm managers or your contracted farmers. Pallet labels can be scanned directly at the farm, which gives you a real time stock position at a farm or truck. This information will help your production planner to know which eggs will or can arrive soon and that helps to optimize your planning.

Various ways of using Hatchtrack On Farm Scanning

As every single customer is unique, the On Farm Scanning application can be used in different ways and for multiple goals. In this article we will zoom in on Emsland Brüterei and how to realize real time stock control of hatching eggs at all farms and trucks.

All contracted farms are registered in Hatchtrack and have their own Hatchtrack pocket PC. All farm trolleys have a unique data matrix code with a trolley number. When a trolley is full of hatching eggs, the farmer scans the trolley and will enter information, such as date of lay and - if different than default - quantity of eggs. In the Emsland office, an overview per farm is available with the real time stock. This helps the office to schedule a pick up for their truck drivers.

When the truck driver is collecting the trolleys at the farm, he scans all farm trolleys. After scanning a trolley, the truck driver can see all registered information on the particular trolley and if needed it can be adjusted. After scanning all trolleys, the stock position will change from ‘farm’ into ‘truck’. A delivery note will be created and in the hatchery they can see which eggs they can expect in order to make a production planning.